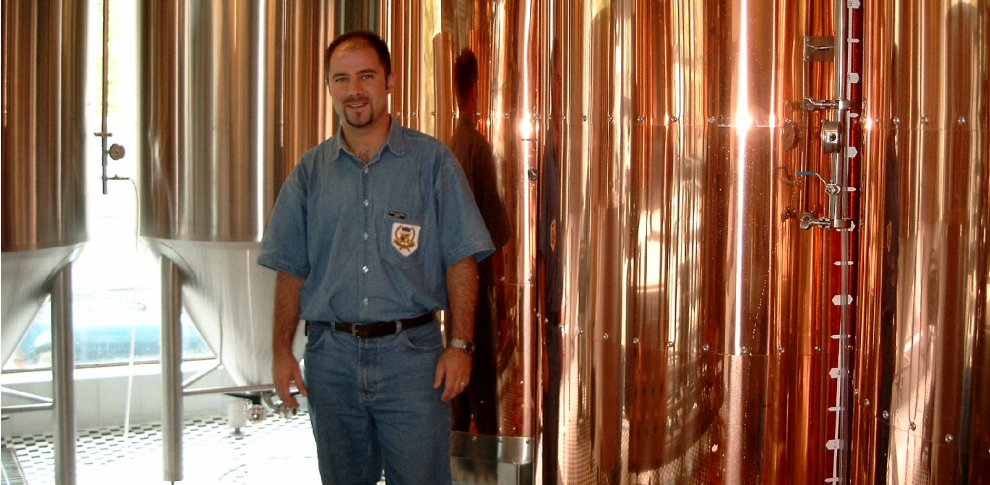

Microbrewery consisting of 5 hl stainless steel brewhouse, electrical heated, 10 hl hot water tank, malt mill, 1 CCT 5 hl, 3 CCTs 10 hl,

3 horizontal lager tanks each 5 hl, 2 horizontal lager tanks each 10 hl, 1 BBT 10 hl, 1 semi-automatic bottle filler + labeler, keg washer,

glycol unit, small CIP, small mobile steam generator

Year of construction: 2019.

____________________________________________________________________________

One-way bottling line, CIME Careddu, type DPS 6/6/1, made in 2019, for 0,25l and 0,33l glass bottles, capacity appr. 900-1.000 b/h.,

with self-adhesive labeler, rinser, filler, corker, collecting tables in inlet and outlet

____________________________________________________________________________

2 x 30 hl CCTs, manufacturer Plevnik, Slovenia, made in 2012, jacketed and insulated, CIP, mandoor on top, outlet in cone, 1,5 bar

____________________________________________________________________________

Fully automatic counter pressure bottle/5l can filler, linear machine, made by Gruber/Austria in 2018, type AFD6 with 6 filling stations,

with IDM, adjusted for 0,33l, 0,5l, 2,0l bottles and 5l cans, capacity up to 800 b/h at 0,33l bottles, with frequency controlled beer pump,

low pressure water spray tunnel, rotary table for inlet, fully automatic crown capper for 26mm and 29mm crown caps, hot water injection,

fully automatic self adhesive labeler with one station, industrial ink jet printer for self adhesive label.

_____________________________________________________________________________

2 x 10 hl beer serving tanks manufacturer Duo, jacketed and insulated, with stainless steel cover, 3 bar, for inliner use,

if requested small air compressor and refrigeration unit can be included

_________________________________________________________________________________

4 x 250l CCTs, made in 2020, never been used, cooling jacket in side wall and cone, insulated, shiny copper cladded, 2 bar working pressure,

double outlet in cone, sampling cock, rotation CIP spray ball, mini-manhole on top, connection for PT-100. Immediately available!

______________________________________________________________________________________

2 x 90 hl CCTs (net), made in 2020 by PSS, dimensions 2.400 x 5.000mm, 2 cooling zones, insulated, 3 bar, 2 outlets DN40, sampling cock,

CO2/CIP arm DN40 with bunging device, CIP-diffuser 360°, dry-hop port at sidewall DN40, PRV, vacuum valve

_________________________________________________________________________________________

Full automatic 6-head bottle and PartyKeg filler, made in 2020, very modern and high quality built, hygienic design construction,

capacity: 1.100 b/h (at 0,3l bottles), 1.000 b/h (at 0,5l bottles). For Ring-Pull off closure, double rinser, filling speed individually adjustable,

bottle detector, servo motor transport between conveyor belt of the filling stations, pneumatic stopper on the infeed conveyor,

infeed and outfeed conveyor with plastic hinge chain band and side guides, collecting tables for infeed and outfeed, very low beer losses,

for all commercially available bottles, each station with separate IDM, CO2 purge before filling, very low oxygen pick-up,

Siemens PLC control, 8 container parameter can be saved, program for machine cleaning.

________________________________________________________________________________________

Complete brewery consisting of: 7,5/15 hl Labu brewhouse (2019), hot water tank 10 hl (Meto 2024), 12 x 10 hl CCTs (Meto 2019), 4 x 20 hl CCTs (Meto 2024)

incl. temperature control boxes, bottle filler made by Pontum 2019, 2 x chiller, air compressor, 2 x centrifugal pumps, gylcol buffer tank, accessoires.

_________________________________________________________________________________________

BrauKon brewhouse system, 20 hl, made in 2020, consisting of 2-vessel system with mash tun/wort kettle with agitator and calandria,

lauter tun, semi-automatic T-control system, 2-roller malt mill with automatic mashing-in via conveyor and pre-mashing system,

whirlpool wort cooling wort aeration system, 40 hl hot water tank department, 3 x 20 hl CCTs, jacketed (made in China),

N2-generator, 2-vessel CIP system, steam generator 500 kg/h, 6-head bottle filling line for 0,33- 0,7l glass bottles, capacity up to 600 b/h, air compressor.

________________________________________________________________________________________

Empty bottle inspector Heuft InLIne IR, made in 2013, with base inspection, finish inspection, side wall inspection,

residual liquid detection, rejector for infeed faults, rejector for faulty bottles, rejector for feedback into washing machine,

set output of machine 24.000 b/h, maximum filler set output 12.000 b/h, adjusted für APO 0,33l, available right now

________________________________________________________________________________________

100l 6-vessel pilot brewhouse consisting of mash tun with agitator, decoction tun with agitator, lauter tun with rakes and mandoor for spent grain removal, pre-run vessel, wort kettle, whirlpool, wort cooler, mashing and boiling vessels are equipped with heating jacket for superheated water, 5 pumps, 3 agitators, cutting device / rakes, electrical heating with circulation pump for heating with overpressure safety, piping, small electrical cabinet with on/off switches, temperature control of heating system.

__________________________________________________________________________________________

New 2-roller malt mill, capacity appr. 500-600 kg/h, on legs with bag holder, motor protection and ammeter, magnet, eccentric quick set-up of roller distance

__________________________________________________________________________________________

NEW!! Yeast Booster perfect for small and craft breweries

This yeast booster is a compact, mobile and reliable assistant for optimal re-activation, vitalisation and

propagation of yeast. To achieve these goals the yeast booster has following characteristics:

• Gentle heating/cooling • targeted nutrition management for yeast cells • effective oxygenation for the yeast

_________________________________________________________________________________________

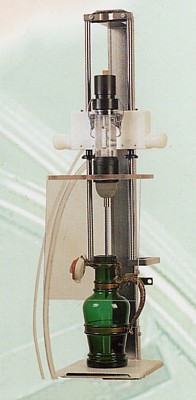

NEW !!! Semi-automatic operated bottle and growler counter pressure filler. Perfect for pub breweries and small craft brewers.

________________________________________________________________________________